Prime Scientific - Why the Kjeldahl Method is the Industry Standard for Animal Feed

The Kjeldahl method (the industry standard test used to routinely measure the crude protein content of foods) measures the total nitrogen content of a food, which is then used to estimate the protein

Introduction

The Danish chemist Johan Kjeldahl (1849–1900) developed what today is well known as the Kjeldahl method for determining nitrogen in organic substances. The original method as presented by Kjeldahl has been continuously improved. These developments have improved environmental and personal safety aspects, increased the speed and versatility of the method, and simplified the entire analytical procedure.

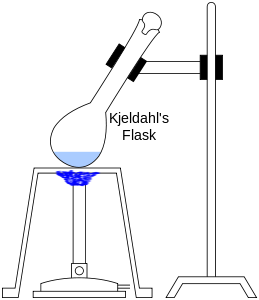

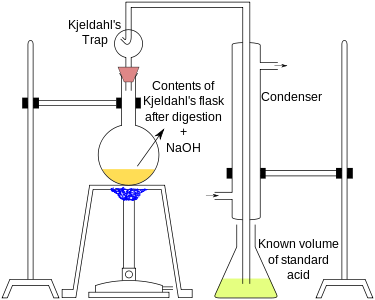

The Kjeldahl method has 3 different steps: digestion, distillation, and titration. Traditionally Kjeldahl flasks with a capacity for 500–800 mL and gas or electric heating have been used for the digestion. For distillation, the addition of water and alkali to the digested sample has been followed by the heating of the flask in order to distill >150 mL distillate. The distilled ammonia has been captured in standardized acid, and back titration with standardized sodium hydroxide has been used.

Today, this method is universally accepted and used in tens of thousands of laboratories throughout the world.

For most sample types, traditional Kjeldahl flask digestion followed by back titration of standard acid or block digestions followed by colorimetric detection are still the only approved Kjeldahl methodologies. For most agricultural sample types, the use of copper catalysts instead of mercury catalysts has been approved, thereby minimizing the environmental hazards of the method.

Kjeldahl, The Industry Standard

The long-time standard for protein analysis has been the Kjeldahl method (AOAC Method 976.05). The longevity of this method is obvious when considering that the method was first published in 1883. In the past, the need to develop faster methods for protein analyses has probably not been perceived to be as important as the need for rapid fat and moisture methods. However, in the past decade or so, product definition and labelling has placed increased emphasis on protein content and the need for rapid, dependable protein measurements is now as great as for methods for moisture and fat. In addition, the heavy-metal catalysts used plus the concentrated acid and alkali waste generated by conventional Kjeldahl procedures have become an increasing disposal concern for laboratories. Some past method developments for protein have included approaches such as dye-binding procedures, but none of these represented major advances in methodology. Improvements in instruments to provide automated, relatively rapid Kjeldahl analysis have included accelerated digestion units and automated, rapid distillation. These instruments are based on the Kjeldahl method but provide for easier, more rapid analysis than the traditional Kjeldahl method.

The Kjeldahl Modern System

Digestion

The digestion units of the behrotest® InKjel series are equipped with efficient infrared heating. The quality and positioning of the behr infrared heaters guarantees the user identical heating phases and digestion temperatures on all sample slots. This also applies to double-rowed arrangement in insert racks for 12 samples. The digestion tubes hang in the rack and do not touch the bottom of the digester. As a result, the digestion vessels are at less risk of breakage than in an aluminium heating block.

Distillation

behr S series steam distillers are the optimum addition to the behr Kjeldahl digestion system. Depending on the requirements, the user can choose between five automatic steam distillers. These have identical basic designs, however, their ease of use and degree of automation differ. The top of the range unit, the behr S 5, is prepared for work with an external titrator.

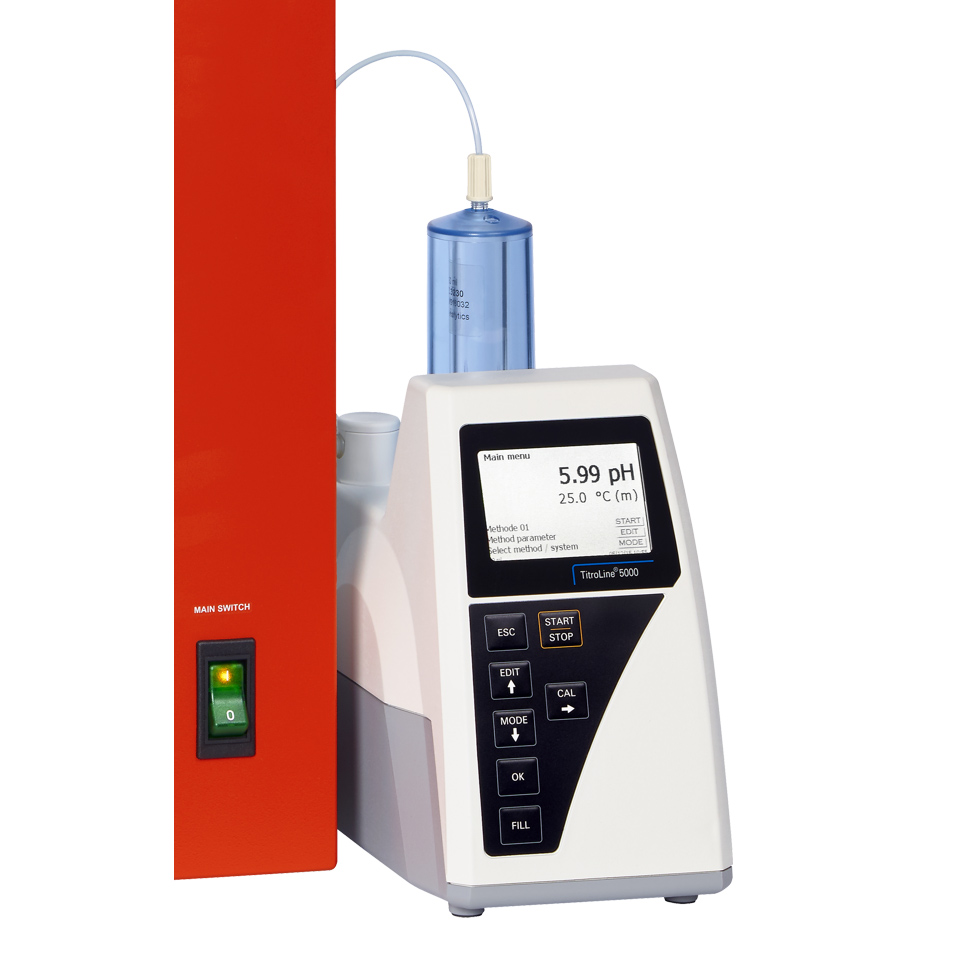

Titration

Titration module for connection to the S 5 steam distilling apparatus, with Kjeldahl method and evaluation.

The TitroLine® 5000 is a very compact titrator for simple routine titrations. Thanks to a selection of standard methods to choose from, the creating of methods as you go is no longer required. Just load the method you need and press the start button. GLP compliant results with titration curve can be documented on a connected printer or USB-memory stick

Acid Scrubber

The two-stage behrosog process extraction system (scrubber) – pre-separator plus safety stage – prevents any acid fumes whatsoever from reaching the environment. Compact process extraction system for extracting and neutralising aggressive acid fumes, especially from the Kjeldahl digestion method for nitrogen determination. An upstream two-stage pre-separator washes out the toxic substances. The process extraction system is equipped with a vacuum pump 40 l/min. There is no need to connect to the water supply.

Experimental Method, AOAC 2001.11

Preparation

Grind dry laboratory sample to fineness of grind (ca 0.7–1 mm), which gives a relative standard deviation (RSD) of ≤2.0% for 10 successive determinations of N in ground mixture of corn grain and soybeans (2 + 1). Fineness required to achieve this precision must be used for all dry mixed feeds and other nonuniform materials. Mix liquids to uniformity.

Digestion

Turn on block digestor and heat to 420°C.

Weigh materials, recording each test portion weight (W) to the nearest mg for weights of ≥1 g, and to the nearest 0.1 mg for weights of <1.0 g. Do not exceed 1.2 g. For materials with 3–25% protein, weigh approximately 1.0 g test portion; with 25–50% protein, approximately 0.5 g test portion; and >50% protein, approximately 0.3 g test portion.

Perform quality control analysis and analyses of standards with each batch.

Add 2 catalyst tablets to each tube. Add 12 mL H2SO4 to each tube, using pipetting dispenser; add 15 mL for high fat materials (>10% fat). Mixtures may be held overnight at this point. If mixture foams, slowly add 3 mL 30–35% H2O2. Let reaction subside in perchloric acid fume hood or in exhaust system.

Attach heat side shields to tube rack. Place fume manifold tightly on tubes, and turn water aspirator on completely. Place rack of tubes in preheated block. After 10 min, turn water aspirator down until acid fumes are just contained within exhaust hood. A condensation zone should be maintained within the tubes. After bulk of sulfur oxide fumes are produced during initial stages of digestion, reduce vacuum source to prevent loss of H2SO4. Digest additional 50 min. Total digestion time is approximately 60 min.

Turn digestor off. Remove rack of tubes with exhaust still in place, and put in the stand to cool for 10–20 min. Cooling can be increased by using commercial air blower or by placing in hood with hood sash pulled down to increase airflow across tubes. When fuming has stopped, remove manifold, and shut off aspirator. Remove side shields. Let tubes cool. Wearing gloves and eye protection, predilute digests manually before distilling. Carefully add a few milliliters of deionized water to each tube. If spattering occurs, the tubes are too hot. Let cool for a few more minutes. Add water to each tube to a total volume of approximately 80 mL (liquid level should be about halfway between the 2 shelves of the tube rack). This is a convenient stopping point.

Distillation

Place 40% NaOH in alkali tank of distillation unit. Adjust volume dispensed to 50 mL. Attach digestion tube containing diluted digest to distillation unit, or use automatic dilution feature, if available. Place graduated 500 mL Erlenmeyer titration flask containing 30 mL H3BO3 solution with indicator on receiving platform, and immerse tube from condenser below surface of H3BO3 solution.

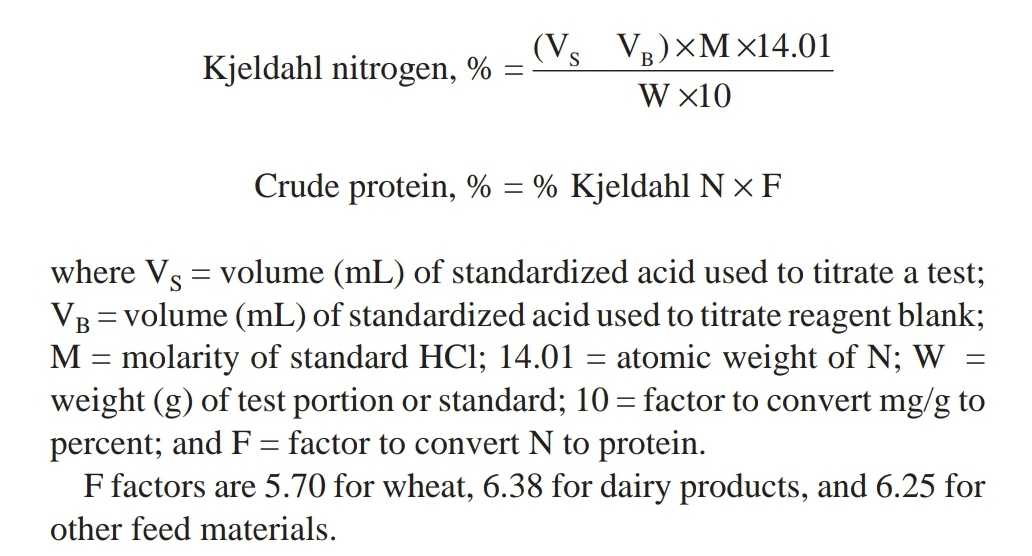

Steam distill until ≥150 mL distillate is collected (≥180 mL total volume). Remove receiving flask. Titrate H3BO3 receiving solution with standard 0.1000M HCl to violet endpoint (just before the solution goes back to pink). Lighted stir plate may aid visualization of endpoint. Record milliliters of HCl to at least the nearest 0.05 mL.

This is done automatically by using a steam distiller with automatic titration. Follow the manufacturer’s instructions for operation of the specific distiller or distiller/titrator.

Determination of Nitrogen

References

- https://academic.oup.com/jaoac/article/85/2/309/5656583

- https://www.sciencedirect.com/science/article/pii/B012464970X00074X

- Brochure_Kjeldahl_method - Behr Labortechnik

- AOAC Official Method 2001.11 Protein (Crude) in Animal Feed, Forage (Plant Tissue), Grain, and Oilseeds Block Digestion Method Using Copper Catalyst and Steam Distillation into Boric Acid

Prime Scientific

Prime Scientific provides equipment, instruments and other related products and materials. We aim to be a one stop shop for all our customers laboratory needs. Since 2001, Prime has strived to provide the best services and solutions to the scientific community in the region.